Rapid Prototype: A Process with Tight Tolerance

When you want to create a product prototype, there are many factors to consider. The first is the process you will use to create the prototype. There are several different methods available. One such method is rapid prototyping. Rapid prototyping is a process that creates a three-dimensional model of a product from a computer file. It is an efficient way to create a high-quality product prototype with a tight tolerance in a short amount of time. In this blog post, we will explore the rapid prototyping process and how it can benefit your product development.

What is Rapid Prototyping?

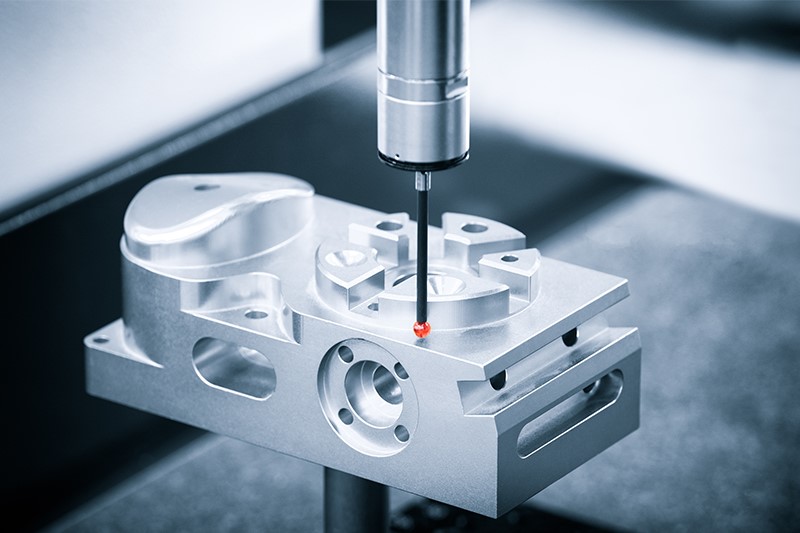

Rapid prototyping is the process of quickly creating a prototype or model of a product. The purpose of rapid prototyping is to produce a working model of the product as quickly and cheaply as possible. Rapid prototyping can be used to test the feasibility of a design, to test how the product will function, or to create a prototype for display purposes simply.

There are several rapid prototyping methods, but the most common is 3D printing. With 3D printing, a three-dimensional object is created from a digital file. The object is built up layer by layer until it is complete. 3D printing is fast and relatively inexpensive, making it ideal for rapid prototyping.

Other methods of rapid prototyping include machining, casting, and molding. These methods are generally more expensive and time-consuming than 3D printing, but they can produce more accurate and detailed prototypes.

Pros of Rapid Prototyping

There are many advantages to rapid prototyping, especially when compared to traditional methods of manufacturing. Perhaps the most obvious benefit is the speed at which prototypes can be created. Rapid prototyping can create a prototype in a matter of hours or days, whereas traditional methods can take weeks or even months. This means that companies can get their products to market much faster, which is crucial in today’s competitive environment.

Another advantage of rapid prototyping is that it allows for much more complex designs to be created than with traditional methods. This is because prototypes can be built up layer by layer, meaning that there are no restrictions on geometry. This gives designers far more freedom to create the products they want, without having to worry about whether or not they can actually be manufactured.

Finally, rapid prototyping is also much less expensive than traditional methods, since there is no need for expensive tooling or molds. This means that companies can save a lot of money on product development costs, which can be reinvested into other areas of the business.

Conclusion

A rapid prototype is an essential process for any business that wants to create high-quality products with tight tolerances. By using rapid prototypes, businesses can create prototypes quickly and efficiently, without sacrificing quality. A rapid prototype is also a great way to test new designs and ideas, before committing to mass production. If you’re looking to create high-quality products, the rapid prototype is a process you should definitely consider. More importantly, you should choose the rapid prototype provided by KAIAO because it can help you better and tell you whether your products are suitable for today’s market.